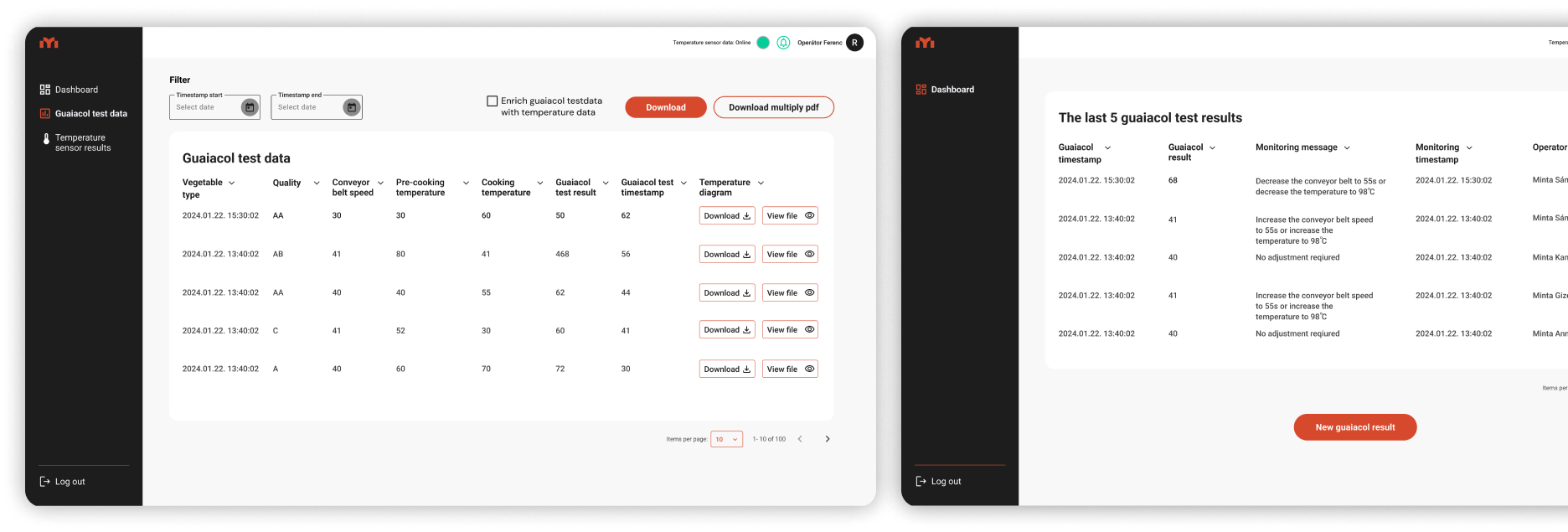

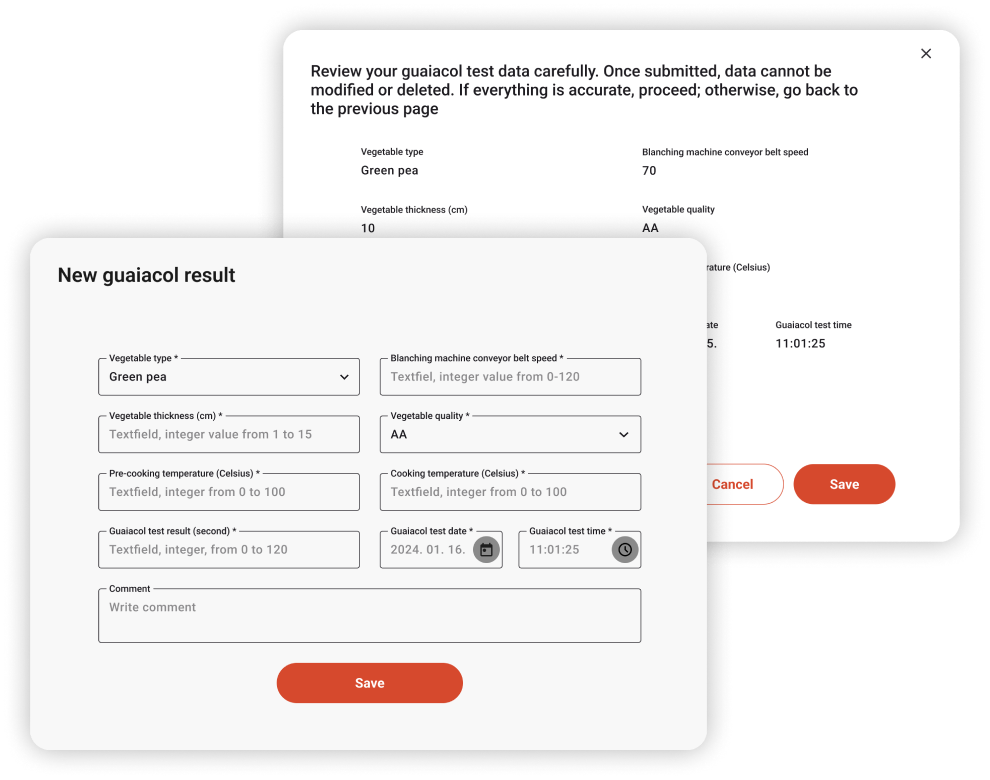

Our MoniTwin solution includes a simple graphical user interface, where the user can look through the connected sernsor’s data, set the „digitalized” machine settings and get a help from the digital twin solution how to change the machine’s current parameters.

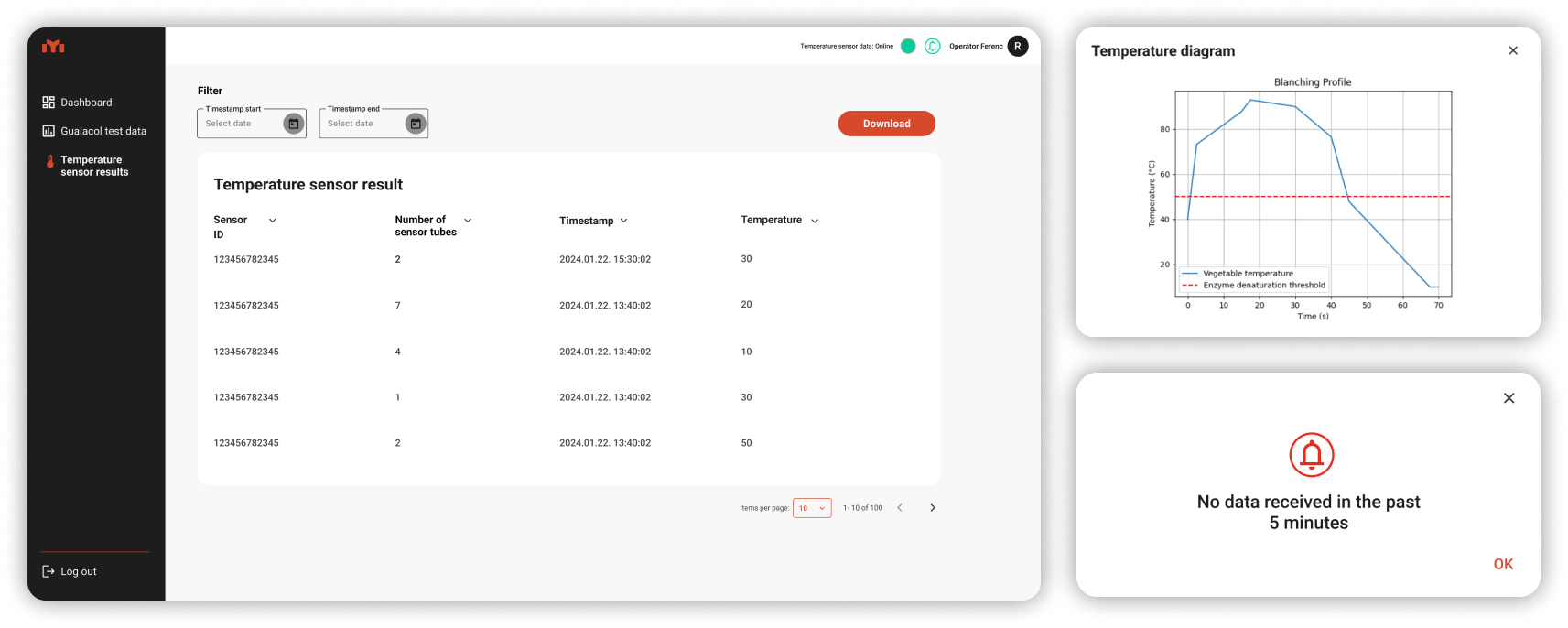

SENSOR DATA

TEMPERATURE

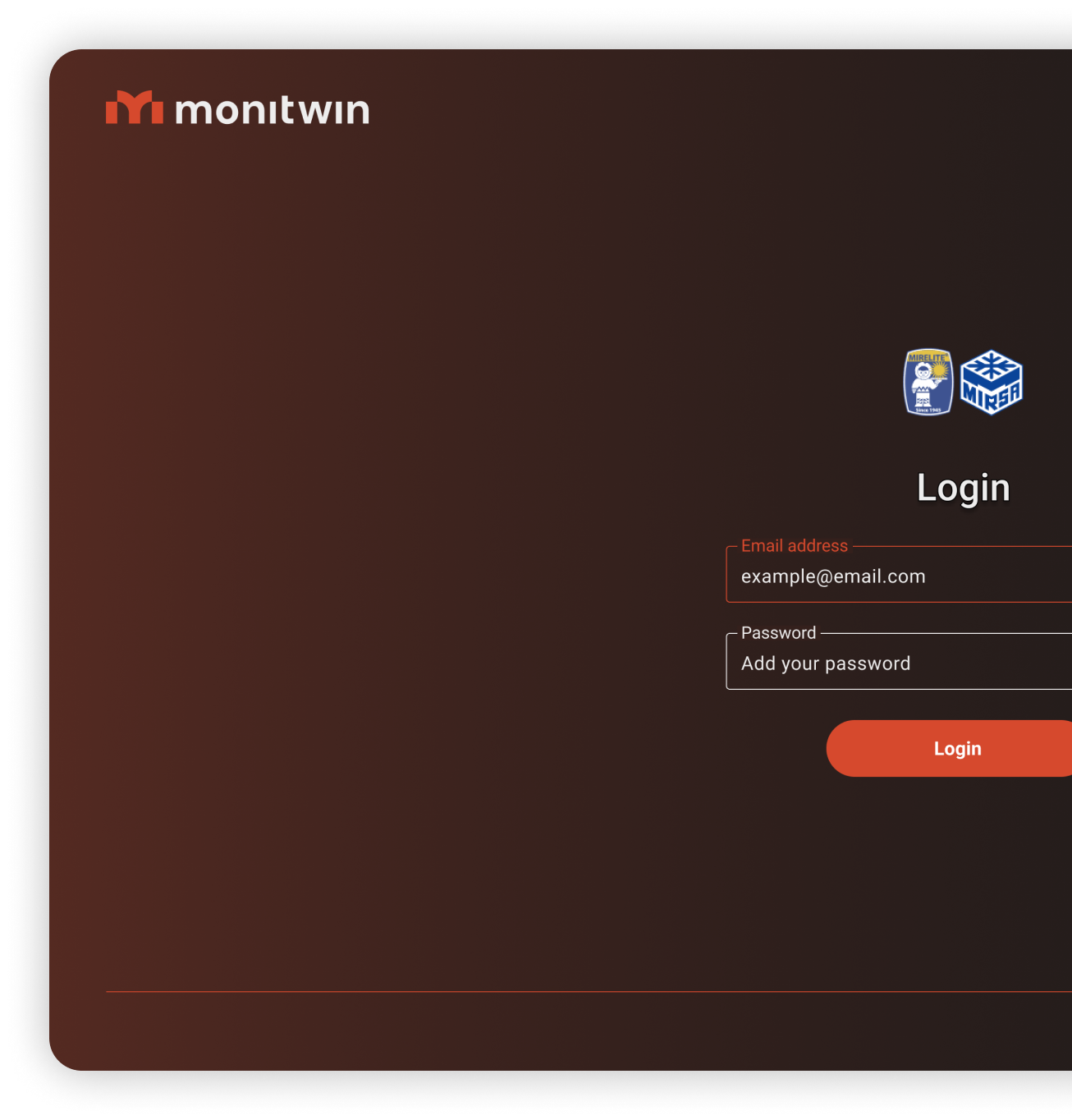

GRAPHICAL INTERFACE

Vegetable params

Process data

DIGITAL TWIN

Guaiacol test

Output

Decision support for configuring process and machine settings

Users can get data from any sensor type and any number of sensors, as well as to upload the current settings of the machine and process.

We collect data from the specific machine’s sensors for 2-4 week interval (depending on the number of products) . Alongside with other machine and process data it will be used to train the AI system in order to develop a Digital Twin model of the process. This model will simulate how changes in the machine’s configuration affect the product, aiding in determining the optimal settings to meet quality requirements while minimizing energy and gas consumption.

Our website uses cookies

Our website uses cookies